XCMG Leads Five Major Deep Integrations to Promote the Optimization and Upgrading of Crane Industry

October 04, 2012

Changes of the overall economic context will expedite the transformation of a certain industry, and an innovation-dominated mainstream company targeting at the growth of quality and connotation will steadily lead this transformation to a breakthrough of optimization and upgrading.

The global crane industry experienced a rapid growth before 2005, and a market rebound between 2005 and 2010. In the mean time, construction projects in the fields of energy and some others propelled the innovation of large-scale hoisting technology, and mainstream companies strove to seize these opportunities to achieve three major breakthroughs: accelerating the speed to meet international standards, subdividing the product structure and categories of cranes, and improving the tonnage. From 2010 to 2012, the demand for cranes reduced due to the tight macro-economic environment both at home and abroad, but the supply capacity increased by nearly two times in the past two years. With intensifying competitions, the crane industry has gone through severe challenges in recent years.

Facing all these ordeals, mainstream companies have to cope with the pressure of competition and seize the regional structural transformation at the same time, with the purpose of realizing the second strategic international take-off and taking the commanding heights of super tonnage in technology. During this process, Chinese companies have displayed the later-comer advantage once again. More and more world records have been created or will be created in China, and a new generation of technology revolution with the theme of enhancing customers' value in use is turning up.

This landmark transition has shown up in 2012; in order to respond to this transition, the five major deep integrations led by XCMG becomes an inevitable trend.

The first deep integration is to realize the deep integration of China's super large crane innovation and application design.

In September 2012, a 3600-ton crawler crane, the largest ultra-ton crawler crane in the world, rolled off the production line in Xuzhou, east China's Jiangsu Province.

The meaning of her birth lies in the integration of "the world's largest" and practical application, rather than the pure pursuit for making "the world's largest" within the industry. Besides, it also marks the first time that the independent innovation of China's super large mobile crane integrated deeply with a large central enterprise user like the Sinopec. The innovative design conducted by combining with the operating mode of practical application filled the blank of China's large-scale equipment manufacturing in this field.

Her birth means a landmark change, namely China's mobile crane industry has discarded the fickleness of blindly pursuing for "the world's largest" in the early days of industrialization, and entered into a new development track of optimization and upgrading.

The second deep integration is to realize the deep integration of China's large-scale mobile cranes and key projects.

In June 2011, the initial application of a 2000-ton crawler crane developed by XCMG turned out to be a great success; on June 8th, 2012, the 2000-ton crawler crane developed by XCMG made an outstanding performance of full-load hoisting in a project of Guangzhou Sinopec; on August 1st, 2012, the 2000-ton crawler crane developed by XCMG played a pivotal role in a refining project in Quanzhou...

Compared with the 2000-ton crane, the thousand-ton cranes have made even more achievements: at the end of 2011, a 1000-ton crawler crane completed full-load hoisting twice in three days in Qingdao, Shandong Province, giving a perfect initial performance; on April 17th, 2012, the thousand-ton crawler crane made by XCMG set foot in the ocean engineering hoisting; on May 15th, XCMG's thousand-ton crawler crane served the ocean engineering again in Penglai, Shandong Province, creating Three New Records...

Moreover, XCMG's 800-ton crane has conducted operations in Qingdao, Hebi and Datong continuously, withstanding the tests of wind-power projects and chemical projects; the 500-ton crane has been listed among regular products and successfully served more than one hundred key projects of over ten industries such as the wind-power, petrochemical, port engineering, bridge, railway, large-scale structural components projects and so on, covering 15 provinces including Hebei, Shanxi, Tianjin, Fujian, Shandong, Hunan, Jiangsu, etc.

The year 2012 shall be remembered in China's crane industry, because countless large projects have testified the high reliability and maturity of domestic equipments through practical application, which not only means the ending of the history in which China's cranes could only serve as auxiliary equipments for hoisting, but also represents that the deep integration of China's large-scale mobile cranes and key projects are moving forward rapidly.

The third deep integration is to realize deep integration with different countries and regions, as well as different user demands.

On June 20th, 2012, XCMG exported a large batch of cranes of above a hundred tons for the first time. To be exact, the export volume was as large as 130. Crawler cranes of above 600 tons have also been exported. These facts mean that the middle and low-end images of cranes made by China's manufacturers, led by XCMG, have changed fundamentally, and the hundred-ton cranes developed in China have been recognized by the international market with higher technology content.

These phenomena indicate that mainstream companies are conducting deep integrations on the international market.

On one hand, China's companies are expediting the construction of research centers in Europe and North America, and investment in setting up factories in emerging countries in the form of joint venture with foreign companies of the same industry.

On the other hand, dedicated cranes designed for different countries and different usage habits such as the desert, oil field, and plateau have been produced successively; an entirely new technology platform centered on the enhancement of value in use (reducing energy consumption without impairing the performance) has been shaped up, and the design theory of "boundary extreme" has drawn wide attention.

This integration will significantly promote the optimization and upgrading of China's industry structure with integration of domestic and international advantages on the basis of fully exploring its own potential.

The fourth deep integration is to realize the deep integration of hard power and soft power.

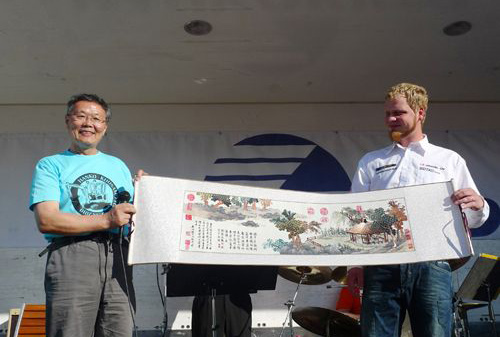

On September 12th, the Second National Hoisting Skill Competition attracted performers from all over the country. It was particularly comforting that quite a few private enterprises designated performers to attend the competition as well.

China's hoisting industry has grown by nearly ten times within the past ten years; however, all sorts of safety accidents are emerging one after another at the same time. Besides, there is still a large distance between the overall skill level of Chinese crane operators and that of the international standard.

XCMG is conscious of the fact that while making breakthroughs of creating world records and enhancing the comprehensive hard power of China's crane industry, manufacturers shall also make a further step forward to frame the relationship between the operator and crane from a strategic height of industry development, undertake the responsibility of making better equipments and fostering excellent talents, and enhance the overall skill level of crane operators. Only by deeply integrating the hard power and soft power of the whole industry, can China's crane industry achieve structural optimization and upgrading and play a more important role on the world stage.

In 2009, XCMG joined hands with six major industry associations to initiate the National Hoisting Skill Competition. Over the past three years, profound experience of improving the skills of operators has been accumulated. In 2012, XCMG and the Construction Branch of China's Architecture Association jointly published the Practical Handbook of Large Equipment Hoisting Engineering, which collected the intelligence of more than one hundred experts from manufacturing and large-scale hoisting companies, making it a reference book of the highest practical value in this industry. Moreover, in 2012, 15 training bases for crane operators have been set up and put into use by XCMG, making a major breakthrough on the virtual simulation training technology of ultra-ton cranes, and difficulties obstructing the practical training of operating ultra-ton cranes were solved ultimately.

Thus, it has become a consensus within the hoisting industry to improve and attach great importance to skills. The deep integration of hard power and soft power will propel the industry to further optimization and upgrading.

The fifth deep integration is to realize the deep integration of industry development and enterprise citizen responsibility.

In addition to the force of constructing the world and making a difference, the crane industry shoulder another special and important mission - fulfilling the enterprise citizen responsibility.

On the sites of various accidents which affect the regular social activities, such as the earthquakes in Wenchuan, Yushu and Yunnan, cranes will always take the responsibility of performing rapid rescue. Meanwhile, hope primary schools, public welfare projects and aid programs are being established and developed one after another with the assistance of crane enterprises.

The prosperity of an industry is not only decided upon the strength of several companies, but the choice of "undertaking major responsibilities, conducting honorable behaviors, and achieving great undertakings" made by the whole group under the leadership of XCMG. In 2012, more and more companies are taking active and spontaneous actions in this regard, hence the deep integration of industry development and enterprise citizen responsibility will surely be helpful to the structural optimization and upgrading of the industry.

Besides, China's crane industry has made a deep integration and construction of the whole industrial value chain. Having gone through years of tests on the market, the complete machine manufacturers are now at the center of the whole industry chain, no matter from the point of scale or innovation abilities. The research and development innovation made by complete machine manufacturers will spur the suppliers to create and reform. For the down stream of hoisting industry, each innovation of products, marketing and service pattern will bring about a series of market responses.

The year 2012 has witnessed abundant changes, in the coming three to five years, the product spectrum of cranes ranging from hundred-ton to thousand-ton levels will be more intensive, and the technology will be more mature. In the mean time, Chinese companies will gradually calm down from the ecstasy of creating a series of world records, and integrate deeply with the project application and user demands. A deep integration within a broader scope and higher level is propelling the industry to achieve structural optimization and upgrading step by step, ushering in the most meaningful landmark transition of the mobile crane industry.