May 23, 2016

Affected by the El Nino phenomenon, Southeast Asian countries have been under a high-temperature state since April, with the temperature of some areas in Malaysia having exceeded 40℃. Days before, LOVOL overseas service personnel came to the sweltering Sarawak in East Malaysia to conduct the over-one-month engineering machinery product itinerary service work, with a view to refreshing customers in the hot weather.

Palm is a primary agricultural pocketbook of Malaysia, and the country is now in the busy season of palm oil processing. LOVOL loaders can be often seen in many palm processing factories. Since the entry into Malaysian market in 2006, LOVOL loaders have been recognized by local users for its excellent product performance, ideal driving comfort, and high operation efficiency, and has therefore seen an increasing growth of both the sales volume and market share.

After arriving in Malaysia, LOVOL service personnel had to travel over 200km every day to maintain machines for users, and train them in product knowledge. At about 10:00 p.m. on May 4 when service team members just returned to their lodging for supper, they suddenly received the call from a palm fruit processing factory user on a failure of a LOVOL loader. After learning the condition, the service team drove to the destination.

At about 12:00 p.m., they arrived at the palm fruit processing factory, and saw a dozen of LOVOL loaders operating in the storehouse of palms. At a corner of the storehouse, there parked a LOVOL FL958G loader. According to the factory owner, this loader worked well, but it suddenly slid backwards upon releasing of the brake after a braking operation at a slope today. He was not sure which part went wrong, and hoped that the problem would be solved as soon as possible.

The service personnel found a slope on site to demonstrate the scenario, and confirmed what the user had said. As the new LOVOL FL958G loader has been installed with the power cut function, the power output will be cut off automatically in braking to detach the clutch for the sake of protection. After opening the cover of the electric box, the service personnel found that the harness connector of the signal collection module became loose. He reset the connector and asked the driver to test, then the loader did not slide back any more.

After the troubleshooting, the factory owner expressed his thanks. He said, "Our factory has been using LOVOL loaders since 2008, and the product is really our right hand as it is easy in driving, flexible in steering, and efficient in operation. Meanwhile, LOVOL does very well in its after-sales services, and is speedy in door-to-door services. They came at midnight to repair our machine today, and their dedication moved me a lot. So I firmly believe in this brand, and will continue to select LOVOL products next time."

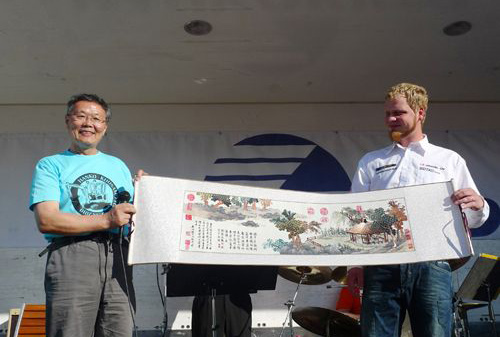

After over 30 days of stressful and high-efficiency services, LOVOL service team succeeded in finishing all tasks. In their mind, the best harvest is to win customers' respect and trust. LOVOL service team has, through the delivery of considerate services, interpreted the service concept of "LOVOL service is all for you", improved users' satisfaction, as well as safeguarded the sound operation of LOVOL's overseas businesses.

At 6:00 pm on 29th June, a SWE17B excavator with provisional license plate appeared, the waiting cro

May 29 ~ June 2, the M&T EXPO was held at Immigrants Exhibition Center in St. Paul, Brazil. During the exhibition, Shandong Lingong exh

On November 7, the opening ceremony for Phase III Training of XCMG Public Welfare Project -- "Global Excellent Operator" was held in XCMG, where Li Ge, the Deputy Secreta

What is breaking force deficiency? It is when you press the brake pedal down, the loader does not slow down or stop as required. The main causes include: ① The brake system i

Copyright Notice 2002-2026 global-ce.com Construction Machinery Online. All rights reserved.

Address: Room 901, Building C, Ruipu Mansion, Hongjunying South Road No.15, Chaoyang District, Beijing.100107 P.R.China